Unveiling the secrets of Tunnel Boring Machines!

What is a Tunnel Boring Machine (TBM)? What are the components of a TBM? How do these components work in tunnel boring projects?

A TBM is a large-sized unit specially designed for tunnel construction. The main functions of a TBM are: drilling tunnels, transporting debris and installing tunnel walls.

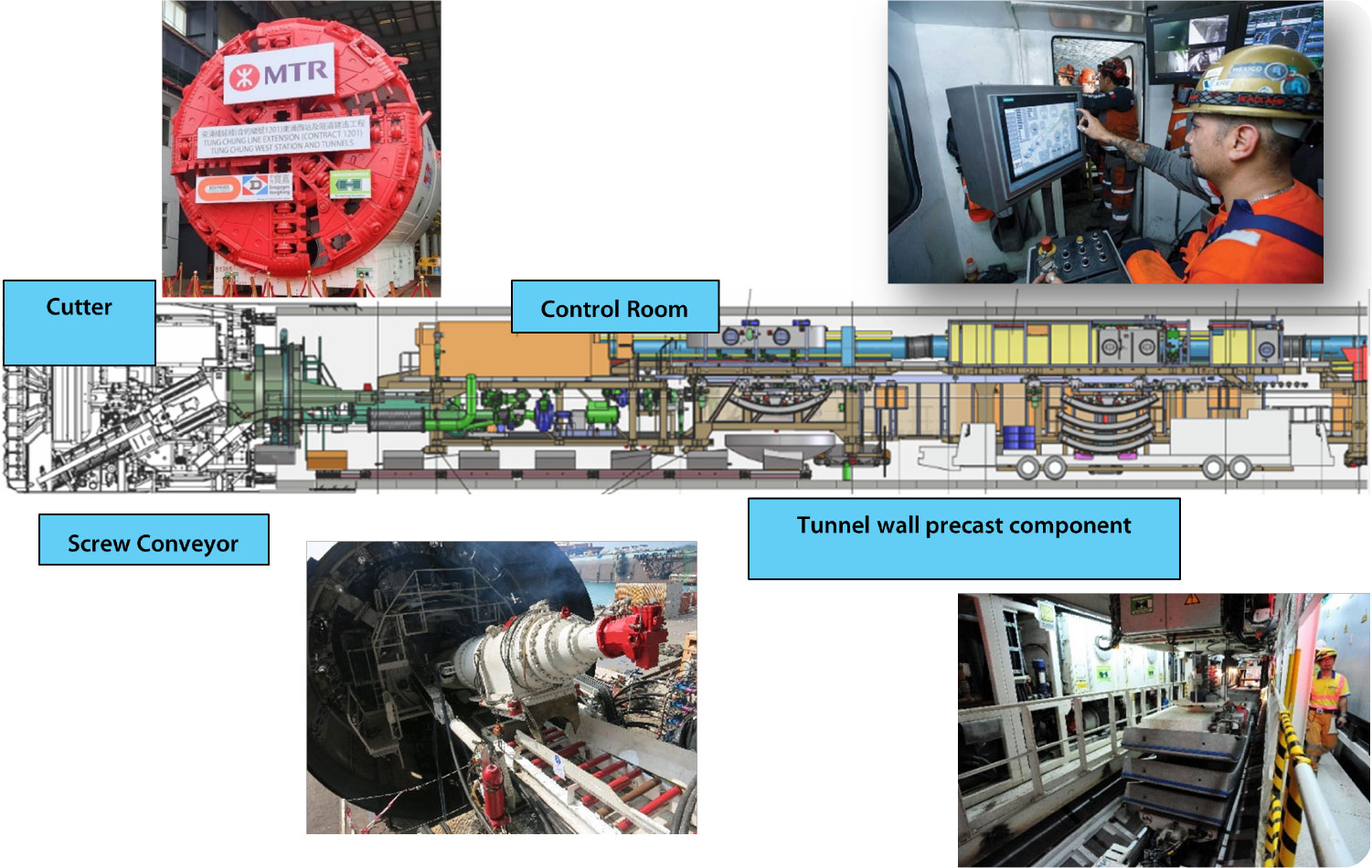

The TBM consists of a cutter head, a control room, screw conveyor and a tunnel wall precast component placement system. The cutter head is located at the front end of the TBM and is equipped with a metal rotary cutter head, which is responsible for excavation as the TBM moves forward. The TBM is able to drill in different types of rock layers when it is equipped with different cutter heads.

Behind the cutter head is a large body, with the front part being the control room, where professional engineers control the forward movement of the TBM, pressurization and depressurization, installation of the tunnel walls and replacement of the cutter head. The excavated material is processed into slurry inside the TBM and is then transported to the rear of the TBM by the screw conveyor. The slurry will later be transported to slurry treatment facilities for subsequent treatment.

The middle section of the TBM is the tunnel wall precast component placement system, which is used to transport the tunnel wall precast components to the front of the TBM. While the TBM is drilling, the tunnel wall will be installed at the same time, which greatly improves the efficiency of the project.