There are many ways to excavate tunnels, why do we use Tunnel Boring Machines?

| Tunneling Methods | Features | Suitable Place |

| Cut & Cover | Lower risk of collapse or subsidence | Suitable for shallow excavation in soft ground |

| Drill & Blast | No disruption to road traffic | Suitable for areas without sensitive receivers |

| Requires a relatively small construction site | ||

| Tunnel Boring Machine | Reduces the area of ground excavation, minimising the impact on the community and road traffic | Different types of soil, rock or mixtures of both |

| Reduces the impact of dust and noise | ||

| Simultaneous installation of tunnel walls to improve efficiency and shorten the overall construction period | ||

| Immersed Tube Tunnel | Requires a relatively small construction site | Applicable only to the construction of submarine tunnels |

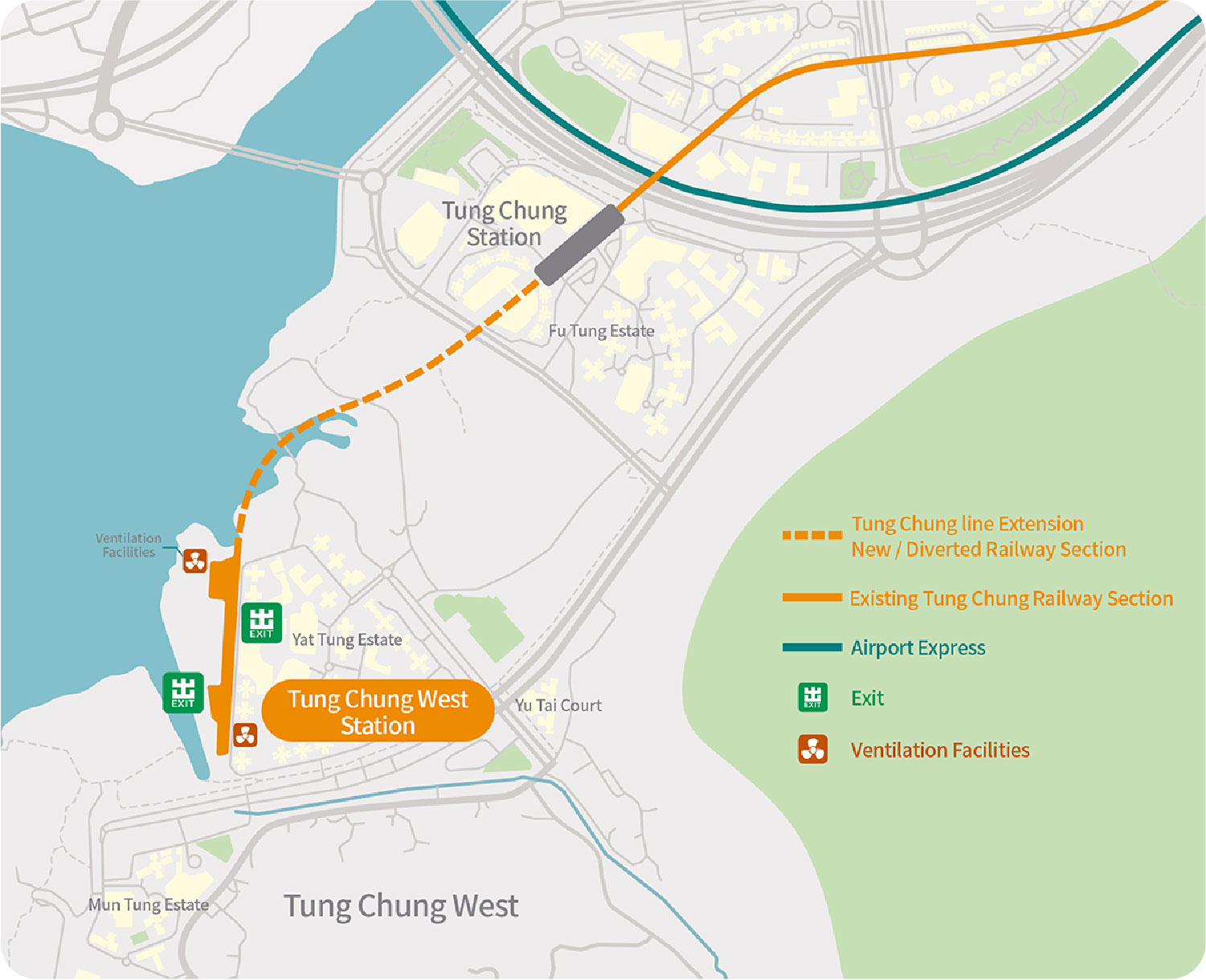

The Tung Chung West section tunnel extends from the end of the existing Tung Chung Station tunnel to the future Tung Chung West Station. Like Tung Chung Station, the future Tung Chung West Station will be an underground station with a number of buildings above and around the alignment.

After a series of investigations along the alignment, such as the soil quality and construction space, the project team chose to use Tunnel Boring Machine (TBM) for the construction of the Tung Chung West Tunnel. The works to be carried out by the TBM are underground, which is a more effective way to minimise the impact of dust and noise.

The TBM will also install the tunnel walls at the same time as the tunnels are being constructed, which is highly efficient. The tunnel walls serve to stabilise the ground level, prevent soil erosion and reduce the potential impact on the adjacent building structures.

Trivia:

The total up-and-down length of the Tung Chung West Tunnel is about 1.3 kilometres and a total of about 6,400 tunnel wall components will be installed during the construction process.